We Specialize in Emergency Transformer Replacements

If you have an emergency power outage call 800-232-9002 to contact our Rapid Response Team

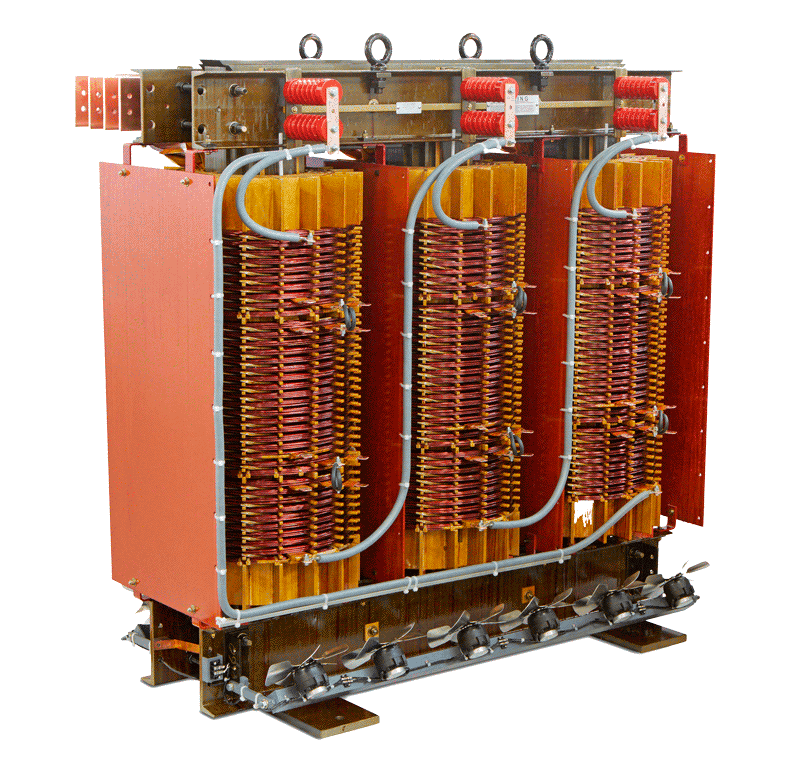

Dry Type Transformers

Having the right dry type transformer is essential to ensuring you have adequate power for your equipment. Whether you’re upgrading preemptively to replace an aging unit or buying an emergency replacement to minimize downtime, ELSCO Transformers has an extensive selection and immediate availability to suit your needs.

Our In-Stock and Ready-to-Ship Dry Type Transformer Selection

At ELSCO Transformers, we specialize in emergency transformer replacements in the 500 to 2,500 kVA range, with voltage options of 2400, 4160, 12470, 13200 and 13800.

Our custom bus work and retrofitting options set us apart. With retrofitting, we modify our units so they fit your existing setup. This service saves you the money you would have spent replacing an entire system. You also spend less time than you would waiting for a custom unit to be delivered and installed.

Some of our popular dry type transformers include:

We have many more 500 to 2,500 kVA transformers available in stock as well. We’ll be happy to answer any questions you might have about our high-quality medium voltage transformers.

Wherever you’re located, our large, in-stock dry type transformer selection is ready to ship nationwide. Orders leave the facility within 24 to 48 hours depending on the required modifications. We also offer a five-year warranty on indoor-use dry type transformers, far exceeding the one-year industry standard you get from most of our competitors.

ELSCO Dry Type Transformer Specifications

Though our dry type transformers’ specifications differ between models, all consist of the same core materials to ensure optimal performance. Our locally produced transformers are stocked at our factory warehouse in Ohio.

We manufacture our dry type transformers with copper conductors due to their high-conduction ability. The windings are categorized as follows:

- Disc: Mostly used in core-form transformers of 25 KV or higher, disc winding is also used in 5 KV and 15 KV designs.

- Primary: Covered with magnetic Nomex-insulated copper wire or film covered round copper wire, primary windings comprise round coils with slotted combs.

- Secondary: Similarly, secondary windings are sheet wound copper with Nomex insulation for better short circuit strength in our dry type transformers with a basic insulation level (BIL) rating equivalent to liquid-filled transformers.

Round or circular coils are superior in design to rectangular ones because they are more durable, making them better able to sustain the workload generated by medium and high voltage transformers.

We offer customized bus work and retrofitting, and we can build a transformer to suit your business’s unique needs. If you’re not facing a power emergency and have a little time to wait, we’ll design and produce a customized model to fit your ideal core and coil assemblies, high and low voltage ratings, K-factor designs and other features.

We are fully committed to delivering exceptional quality. Our transformers offer unsurpassed durability thanks to their robust structure and outstanding material composition. The specifications are designed for high performance and output so you’re never left in the dark.

Dry Type Transformer Applications

Whatever and wherever the need, our ELSCO dry type transformers suit most indoor and outdoor applications that require uninterrupted power supplies. NEMA 1 and 2 are ideal for indoor use, while NEMA 3R with thermostats are best used outdoors.

Our products facilitate a constant supply of electricity for these and other demanding operations:

- Correctional facilities

- Electrical contractors

- Universities and colleges

- Electrical supply facilities

- Hospitals and medical centers

- Just-in-time industrial suppliers

- Continuous process manufacturers

We advise against using dry type transformers outside due to their sensitivity to adverse weather. If you do elect to use one of these units outdoors, they require a special enclosure for protection.

The ELSCO Dry Type Transformer Warranty

Our new dry type transformers hold a five-year warranty against workmanship defects and material degradation with normal wear and tear. Remanufactured units come with a three-year warranty with the same provisions.

Our team is committed to ensuring each individual unit lives up to our superior manufacturing standards, and we have the service record to prove it. We’re proud to note that we’ve had zero reported product failures on our new dry type transformers due to quality, materials, workmanship or design issues since we started building them in 1988.

Why Choose ELSCO Transformers?

If you’re still not convinced, here are a few reasons why you should choose ELSCO Transformers:

- Pollution-free operation: Because dry type transformers contain no liquids and therefore pose no risk of leaking, they promote a healthier, safer environment.

- Reduced fire risk: A lack of combustible oil coolants reduces fire risks, especially in hazardous areas like chemical manufacturing facilities and petrochemical plants.

- Adverse environment suitability: Our transformers are suitable for most indoor environments, including those in areas with seismic activity, because of their incomparable coil and core moisture protection.

- Easy installation: Our customized “plug and play” retrofit devices easily replace old and broken transformers, cutting time waiting for a new one to be fitted. They can be placed in indoor and outdoor applications.

- Superior materials: Built with premium Dupont Nomex insulation and SG200 fiberglass, our transformers deliver exceptional efficiency and quiet, cost-effective operation. These high-quality materials promote excellent longevity.

- Longevity: Our dry type units have a 30-year service life expectancy due to their unparalleled material strength and build quality. These units resist short circuits and excessive heating well to keep the chance of premature failure to an absolute minimum.

Our dry type transformers have numerous benefits, all designed to impact your bottom line positively and maintain reliability in your facility.

Request a Quote for a Dry Type Transformer for Your Business Today

At ELSCO Transformers, we want to save you money by providing the best products and services available. Our dry type transformers are made of superior-grade materials for added durability in all applications. You’ll spend less on maintenance and service costs over the long term.

If you experience a power outage, our Quick Response Team can replace your transformer quickly to get you up and running again. Request a quote for a dry type transformer to optimize your business’s performance and efficiency, or call us at 800-232-9002 today to speak with a team member.